In today’s interconnected global economy, supply chain contracts are critical. They buttress the complex networks that underpin business operations across industries. These contracts’ effectiveness and reliability can shape an organization’s ability to withstand and swiftly recover from disruptions. A recent survey of 800 C-suite leaders and senior executives revealed that supply chain disruptions rank among the top five business risks today.

Supply chain disruptions bear significant repercussions, particularly for the finance, production, and technology sectors. These problems can rapidly undermine operational efficiency and profitability. As such, businesses need to prioritize supply chain resilience. Contracts must clearly address supply chain contingencies with precision and foresight.

This guide will cover the role of contracts in supply chain management and best contract practices for supply chain risk management .

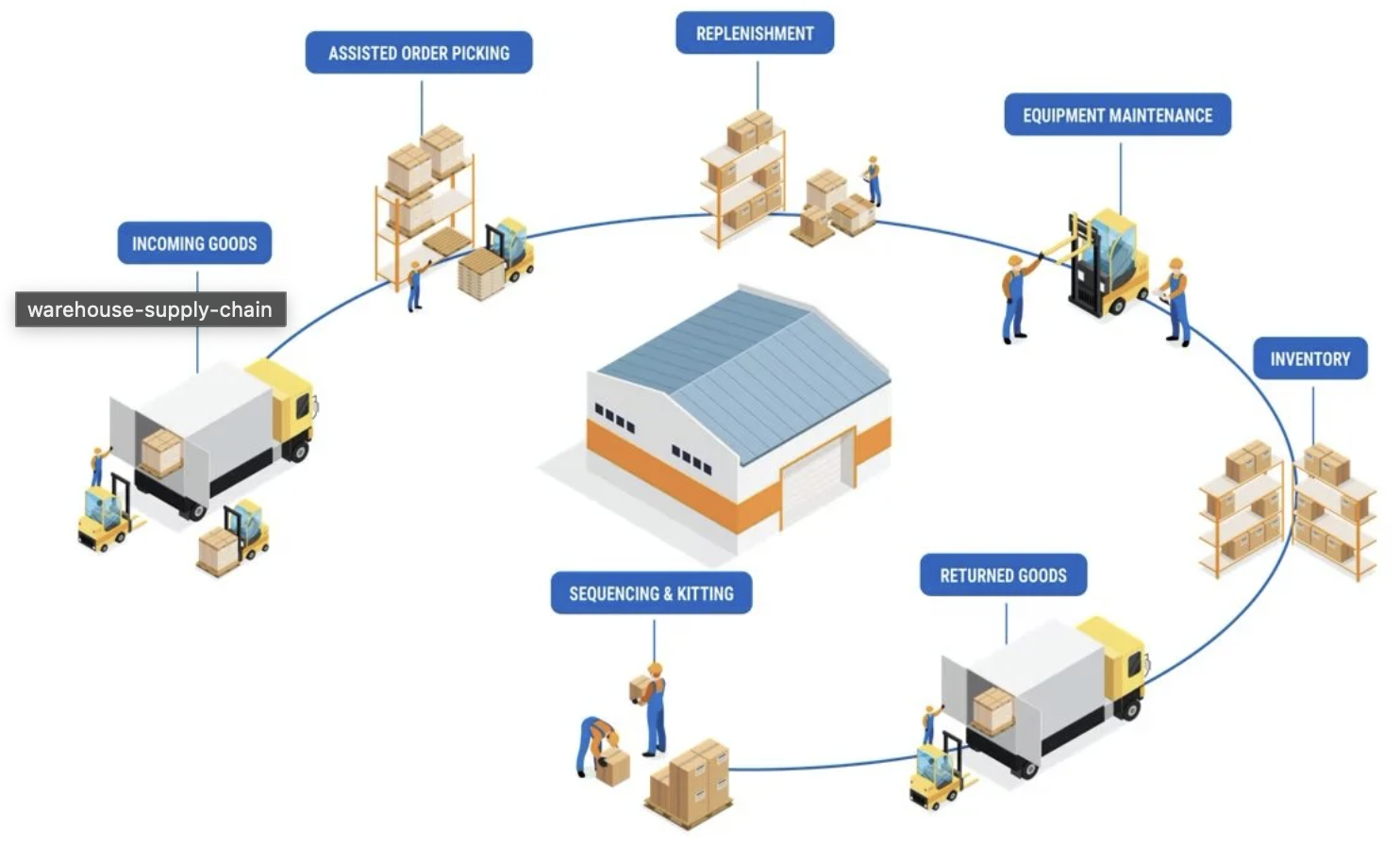

Image Source: https://www.teamviewer.com/en/info/supply-chain-management

In supply chain management, contracts define the parameters of performance, quality, and delivery. These terms legally bind different organizations in the supply chain network. Contracts specify the obligations and expectations between buyers and suppliers, establishing a reliable framework for managing the flow of goods and services.

The efficacy of supply chain contracts lies in their clarity and comprehensiveness. They must have clear terms and conditions to navigate actions and decisions, especially during unforeseen circumstances. A well-drafted contract not only outlines the scope of work and delivery schedules but also anticipates potential disruptions and incorporates provisions for such events, safeguarding continuity and mitigating risk. For these reasons, 57% of companies view effective supply chain management as a competitive advantage.

Additionally, supply chain contracts are instrumental in allocating risks and responsibilities. They specify which party is liable for issues such as delays or quality concerns, reducing the potential for disputes. This clarity is crucial in complex supply chains where multiple stakeholders, from production to delivery.

Effective risk management in supply chain operations depends on the strategic use of contractual agreements. Contracts must address and distribute risks appropriately, with detailed provisions for due diligence and regular risk assessments. These assessments inform the ongoing management and mitigation strategies within the contract, providing clear guidelines for both parties in the event of a supply chain disturbance.

Contracts can also enforce compliance with these strategies. They define consequences for non-compliance, ensuring all parties know their responsibilities in maintaining the integrity of the supply chain.

To fortify supply chain resilience, contracts need clauses that anticipate and mitigate disruptions. Here are three critical contractual elements that serve this purpose:

This clause releases parties from obligations without penalty during extraordinary, uncontrollable events or circumstances. It protects against unforeseen disruption penalties.

These provisions outline specific conditions under which parties may exit the contract. They provide a structured approach to ending agreements when continuing is not in the strategic interest of the parties involved, ensuring minimal impact on the supply chain.

These clauses stipulate the necessity for regular assessments and upgrades to processes, products, or services. They ensure the supply chain adapts to new challenges and opportunities for efficiency.

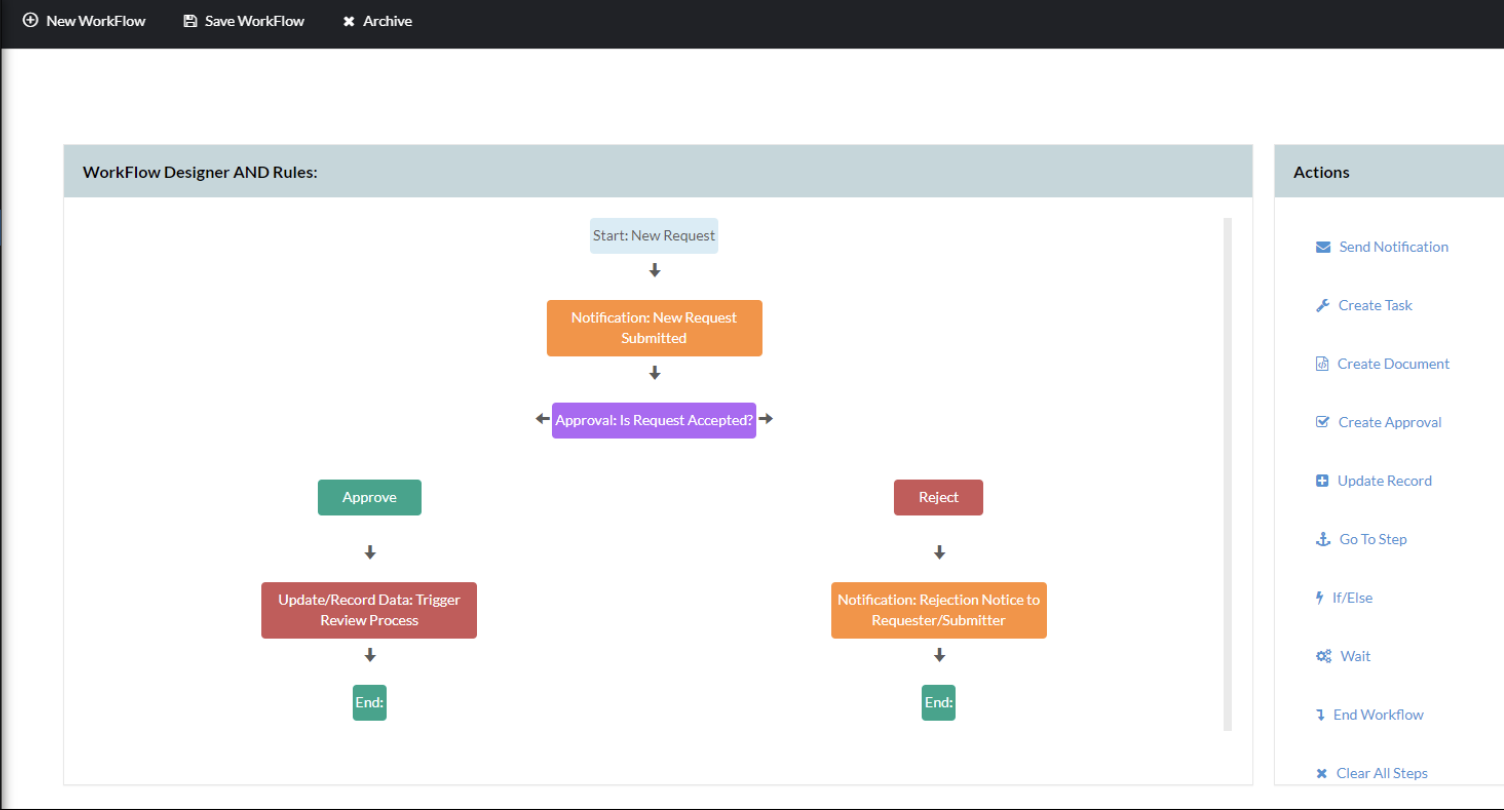

Contract management software is one of the most important tools for strengthening supply chain contracts. Here are some of the ways contract management software plays a pivotal role in reinforcing the resilience of supply chains:

It facilitates the monitoring of contractual obligations, ensuring that suppliers adhere to predefined standards and conditions. This vigilance helps prevent deviations that may lead to supply chain vulnerabilities.

It assesses supplier performance against contractual metrics, enabling companies to address issues before they escalate into critical disruptions.

Contract management systems offer real-time insights into the status of various contracts, enabling supply chain managers to detect and react to risks promptly.

Advanced analytics capabilities within these systems can forecast potential disruptions by analyzing patterns and trends, allowing companies to preemptively formulate contingency plans.

By systematically identifying and documenting risks within supply chain contracts, contract management software aids in implementing risk mitigation strategies.

Automating routine contract-related tasks and workflows reduces the likelihood of human error and increases the efficiency of supply chain operations.

A single, searchable repository for all contracts simplifies management and retrieval, which is crucial during rapid response situations.

The software maintains detailed records of contract modifications, approvals, and communications, which is essential for accountability and in resolving disputes.

Contract management tools often include features to facilitate communication and collaboration with suppliers, ensuring all parties are aligned and responsive to changes.

Alerts for contract renewals prevent lapses in service or supply, which could otherwise lead to gaps in the supply chain.

Elevate your organization’s contract management process with Contract Logix’s advanced software. It offers robust features for contract creation, execution, and real-time monitoring, empowering you to optimize supply chain resilience. With Contract Logix, ensure comprehensive compliance and swift adaptability to market changes.

Looking for more articles about Contract Management? Check out our previous article “Navigate CLM Success: The Do’s and Don’ts of Contract Lifecycle Management“.